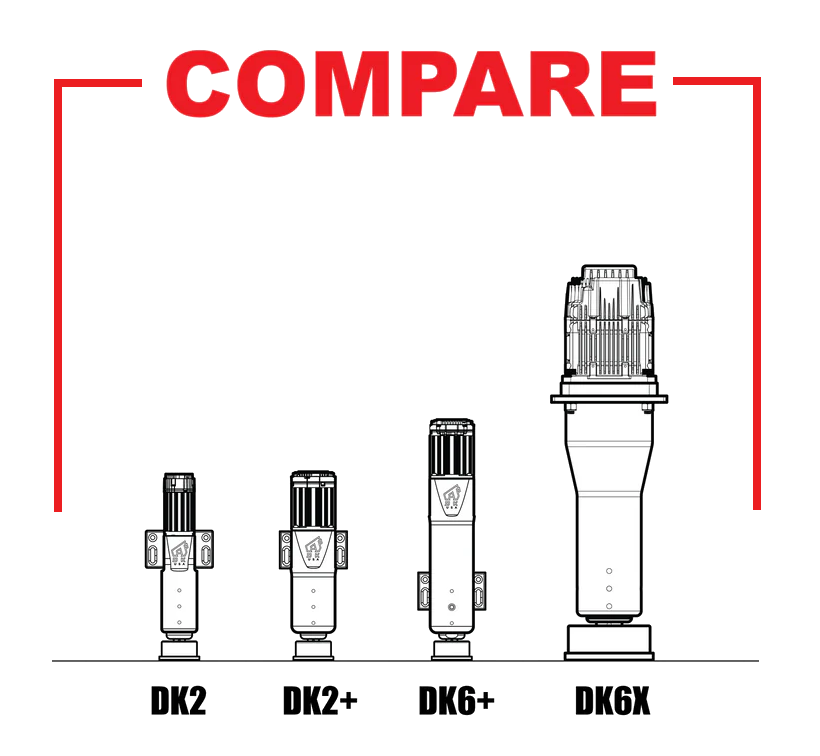

The DK motion product line was specially designed for the best performance, service life and ease of manufacturing in the USA.

Sigma has a long standing history of integrating various linear motion systems for special projects such as these custom built spring assisted Tolomatic RST actuators for the Dodge Demon Dueling Simulators. Tolomatic is just one of over 200+ actuator manufacturers world wide with a unique motion solution for the hundreds of potential market use cases.

Everything from materials handling, robotics, testing, medical devices, construction, manufacturing, packaging, automation etc. This typically requires the actuator manufacturer to have custom mounting solutions, custom motor solutions, custom bearings and components, and various other custom assemblies to meet specific applications needs. Many of the actuators are therefore designed to be highly modular, field serviceable, and customizable. This requires that all custom actuators be assembled from sometimes hundreds of individual parts and components.

System modularity adds complexity. It's a natural tradeoff.

When Sigma designed the DK actuator, we went with the manufacturing philosophy of a 1950's USA Made refrigerator. A refrigerator built so tough that to this day, still runs strong in someone's basement or garage as a second fridge or a beer fridge with no maintenance or service required. Sigma's design philosophy is similar.

The best part is no part, and the best service is no service.

So we designed our innovative DK actuators with simplicity and longevity as a core feature. This includes a single Monoblock actuator housing, chiseled by our CNC machines from a single piece of aluminum billet. Solid steal pistons with a special coating, oversized ballscrews, billet mounting plates and a unique integrated foot design.

It would have been much easier to manufacture independent components and just spend time in assembly, but our solid single piece construction uniquely benefits the dynamic nature of haptics in the simulations industry.

1) Actuators made from multiple components require more assembly processes, which add to overall production time and increases the potential of misalignment or errors.

2) Rigid single piece Monoblock components have much better vibrational characteristics, allowing more of our motion algorithms to shine through back to the driver or passengers.

3) The single piece housing is also better at maintaining concentricity or aligning the piston and ballscrew assemblies in repetitive linear motion applications. This keeps the piston traveling true and straight, reducing deflection and preventing accelerated mechanical wear. See our IGUS Case Study!

So as stated above, there are no solutions in engineering, only tradeoffs and compromises.

So what compromises does our design have?

Well our design requires certain components to be permanently press fit into the actuator body at a 0.0001" tolerance to achieve our high level of concentricity. This special operation cannot be reversed as each press fit component is sized and matched to its own actuator housing. Once hydraulicly pressed in, these components cannot be replaced or serviced and are hence are simply replaced and recycled together as an assembly.

All that being said, our rejection and failure rate of components is still below 0.1% or less than 1 in 1000 actuators experience a failure in their lifetimes. This is a number that we are very proud of and worked very hard to achieve and will continue to drive lower over time as we continually improve our designs and processes.

[All rejected actuators are collected, inspected and catalogued for future improvements.]

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.