COMPLETE MOTION SYSTEMS FOR

RACING or FLIGHT

Sigma Integrale builds advanced turnkey motion systems for sim racing and flight. Only Sigma offers Motion Integrity™, ensuring ultra-low latency feedback derived directly from in-game car physics or craft. Every DK motion system is meticulously engineered to replicate the authentic dynamics of vehicle simulations, free from artificial effects. Our team of passionate engineers have optimized DK to deliver a unique and unparalleled haptic experience. Proudly engineered, and manufactured in California.

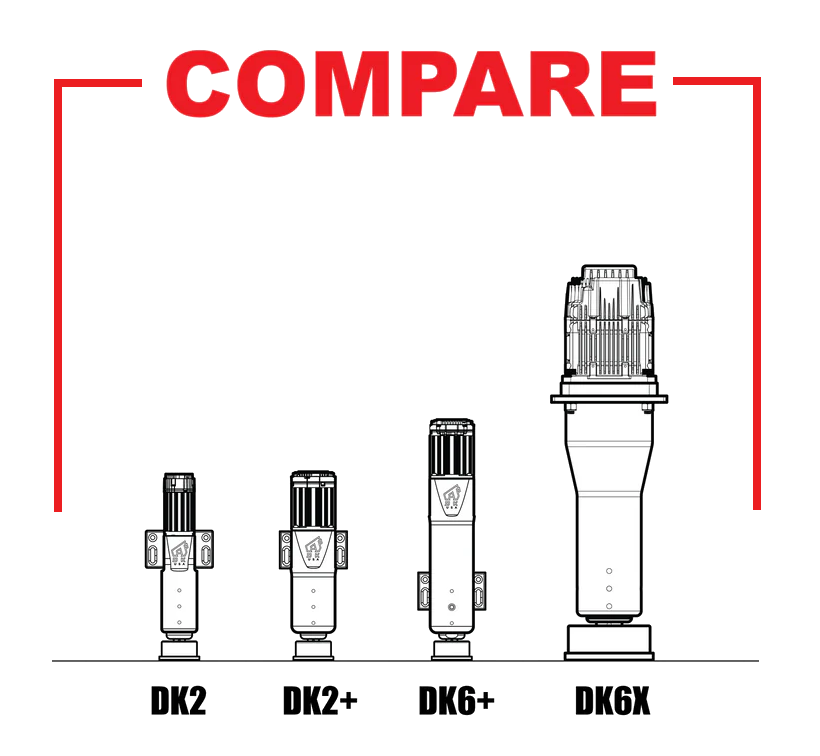

About SigmaWhich DK is for you?

The DK2 motion system is our most optimized motion system, offering exceptional performance for its size and 500 lbs. total capacity and 2 inches of travel.

The DK2+ motion system also has 2 inches of travel, but an increased total payload of 800 lbs. It features larger and more powerful motors designed for heavier rigs and sim centers.

The DK6+ system has the same 800 lbs. capacity as the DK2+ but with 6" of total stroke travel. The additional 4" of travel allows each one of our advanced motion layers more room to express haptics and so its recommended for high travel applications.

0.9 N-m

1.5 N-m

1.5 N-m

500 lbs (227 kg)

800 lbs (363 kg)

800 lbs (363 kg)

2″ (50mm)

2″ (50mm)

6″ (150mm)

"

Sigma has an interesting approach to Sim Racing motion which translates pure telemetry data to the seat of your pants rather than using canned effects...

- Boosted Media | YouTube Review

Why choose Sigma?

01 | Mechanical

The best service is no service.

All DK systems are machined from solid billet aluminum and steel for ultimate rigidity and haptics transmission. Other fabrication methods such as casting, extrusions, 3D printing or the "bend and bolt" methods lack the rigidity to communicate the fine vibrations or haptics.

Each component is machined to the highest level of precision for the best rigidity and haptic transmission. Our machining accuracy also ensures piston concentricity or the unwanted movement of the piston from center when in operation. This feature combined with the Igus dry bearings ensures a responsive, long lasting system with no maintenance required.

Our motion systems are designed for years of uninterrupted service life.

02 | Electrical

Intelligent motion systems require intelligent power.

We are the only company using American made integrated servo motors with an intelligent 75-volt DC architecture. The integrated servo motors are unique in the industry, and although double the price of existing industrial servos they pack three times the performance given their compact size.

The servos combined with our real-time 32-bit ARM controller provide exceptional performance without the massive cabinets, transformers, complex wiring or electrical noise found in other systems. The controller handles complex velocity, acceleration, and jerk calculations in hard real-time (1-50ms). Something that is simply not possible with Windows based motion software algorithms.

Sigma's motion controller is compact and specifically design for the needs of dynamic motion simulation.

03 | Software

Sigma builds unique motion algorithms.

We design, build and continually upgrade our motion algorithms to deliver the best quality haptics. We take a purist approach to motion and only use the given telemetry without relying on canned fake effects.

Canned or telemetry based effects have their place and are useful in filling the gaps left open by some software. However most modern simulation software has all the high frequency data available for a pure motion experience without the use on effects. This makes our software extremely easy to use with very little sliders and configuration needed for whatever vehicle or track. A strong reliance on effects typically means introducing many sliders and settings to try to hide the lack of good data.

Sigma's first principles approach is to do what we can do well, and don't pretend to do what we can't. We call this Motion Integrity and its a key driver in our software development.

Supported Software

Call us at 1-877-742-4482

Sigma Support

Sigma is a customer and product focused company. We direct all our efforts to ensuring that the customers gets the best value and service and this is only possible through direct sales and support. Sigma is the only company that directly sells and supports its own series of products, being as close to you the customer as possible.

News + Updates

Open Universal Telemetry Standard

We have been calling for an Open Universal Telemetry (OUT) standard for a while now. Currently, each simulation software company has their own unique telemetry format or a way of communicating and ...

When discussing latency in motion simulation, its important to realize that there really is no good way to measure latency between various motion systems. In some ways, the latency numbers don't re...

Motion Talk 11 | Assetto Corsa Evo & Rally

Motion Talk 11 compares Assetto Corsa Evo and Rally, showcasing the DK6+ premium motion system. The video details the system's billet construction and Zeta chassis, exploring various car types and ...

I've used a lot of motion systems and nothing compares to Sigma. The speed, tactile feedback, and software is miles above the competition.

In a time where customer service is not a priority in many industries, Sigma's level of hands on customer service is second to none.

Impressive company, fantastic motion system. Very easy to set-up and very responsive.

Have a dk6+ for a couple of months now. Best thing i have for my sim and what a great team. Always ready to help make our sim better every day!