Once a niche hobby, simulation or sim racing has attracted a growing number of enthusiasts seeking virtual motorsport experiences. The popularity surge has fueled demand for professional-grade simulation hardware that accurately replicates real-world racing-vehicle physics, track environments, and driver tactile feedback.

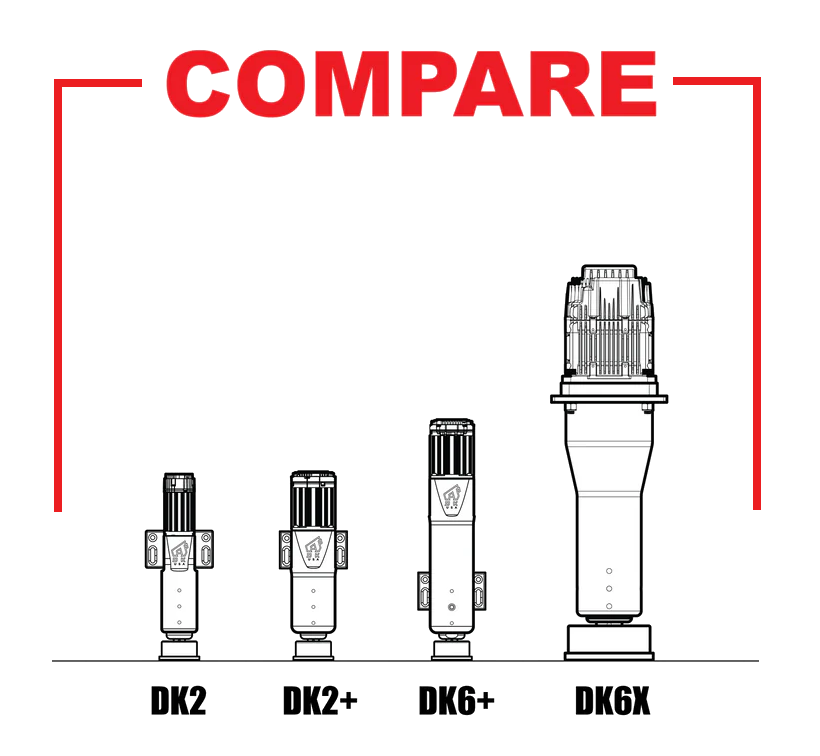

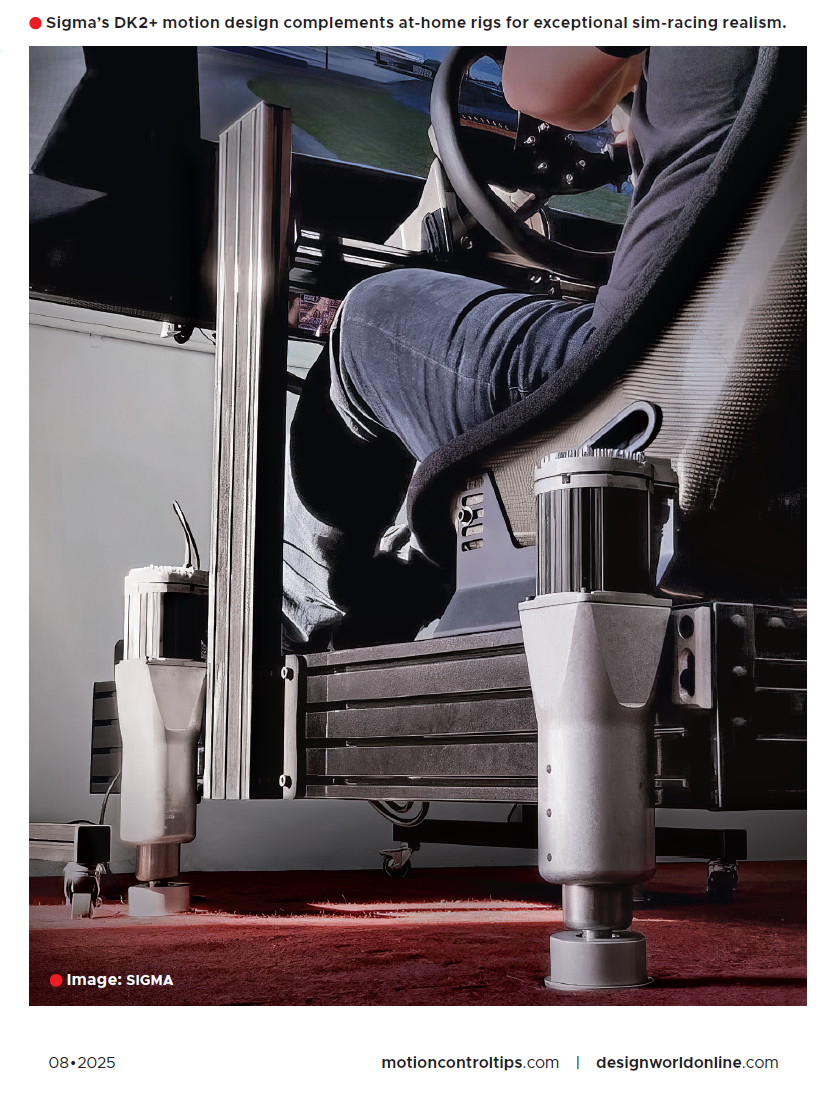

Automotive, truck, and flight-simulator R&D and build integrator Sigma Integrale serves this market with DK-series motion systems. In fact, the company’s patented motion-vehicle technology lets simulator suspension systems move according to the inputs experienced by the driver in virtual environments. Sigma engineers have built

custom, full-motion vehicle simulators for Dodge, Fiat, Volkswagen, and Alfa Romeo. They’ve also re-engineered suspension components, instrument gauges, controls, visual displays and sound systems in everything from go-karts to semi-trailer trucks.

In a recent DK-series design, a top objective was getting maintenance-free linear bearings for a piston mechanism that lifts a simulator frame up and down to mimic driving conditions. More specifically, a Sigma DK6+ system (replicating suspension travel and environmental pitch and roll of dirt ovals and off-roading) features four motorized actuators with 6-in. travel. They’re compatible with any aluminum-extrusion sim chassis via mounting plates.

All DK products feature an aluminum housing and steel piston machined in the U.S. from billet raw materials. Electric motor torque transmits via a coupling to a ball screw. An Igus

JUIO-01-32 Drylin liner lets the ∅2-in. steel piston slide in and out of the aluminum housing while providing side-loading support. An anti-rotation slider 3D-printed by Igus prevents the steel piston from rotating inside the aluminum housing.

Sigma engineers ultimately selected the Igus JUIO-01-32 Drylin liner because it doesn’t need external lubrication — a significant advantage for a consumer product used in homes where users don’t want to deal with greasing. The Igus JUIO-01-32 uses offers dry-running linear motion using tribopolymers for grease-free operation. Known for their self-lubricating properties, Igus liners are manufactured from high performance polymers embedded with solid lubricants. This composition allows for smooth linear motion sans oil or grease, as the embedded lubricants are released during movement.

What’s more, the Drylin liner will never corrode and can operate in environments with dirt and dust. The self-cleaning nature of the liner prevents particles from adhering to its surface, so operation is smooth and reliable. Contact between the guide and shaft reduces surface pressure

is continuous and larger than that of traditional recirculating ball bearings, so operation is quieter … a particularly beneficial characteristic when sim rigs operate in homes.

The Drylin materials are lightweight and corrosion resistant, making them suitable for various applications. The use of materials such as aluminum and carbon fiber for the shaft guides enhances system resistance to corrosion. These polymer liners are lighter than metallic alternatives, and reduced need for lubrication and maintenance trims overall cost.

The Igus Drylin liners provide several benefits to Sigma’s DK motion

systems. Their resistance to wear and environmental factors contributes to the system’s durability and long service life — even under continuous use and high side loading. Sigma engineers have observed that the Igus products hold up well to years of use and abuse sans issues. The liners have not failed even in cases with rougher piston finishes causing excessive wear.

“We’ve used Igus Drylin liners in motion systems for years and have never had a part failure or a return related to the liner,” said Sigma head of engineering

Howard Lin.

“They handle immense load and side pressure. Honestly, we expect them to need service at some point, but they never do.”

The Igus liners take a lot of abuse in a dynamic application and just keep performing consistently, added Lin.

“After spending a long time developing a suitable linear solution, it was impactful to find an off-the-shelf Igus Drylin liner that exceeded expectations and became the core of the motion system. We know we’re delivering a fantastic at home simulation experience because of it.”

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.