When we talk about motion systems with clients, we separate the industry into 3 categories or types of motions systems. These are Turn-Key motion systems, Catalog systems and Do-It-Yourself motion systems. Each category of motion systems has its benefits and tradeoffs and its wise to compare the differences to know which system is right for you.

So let's break it down!

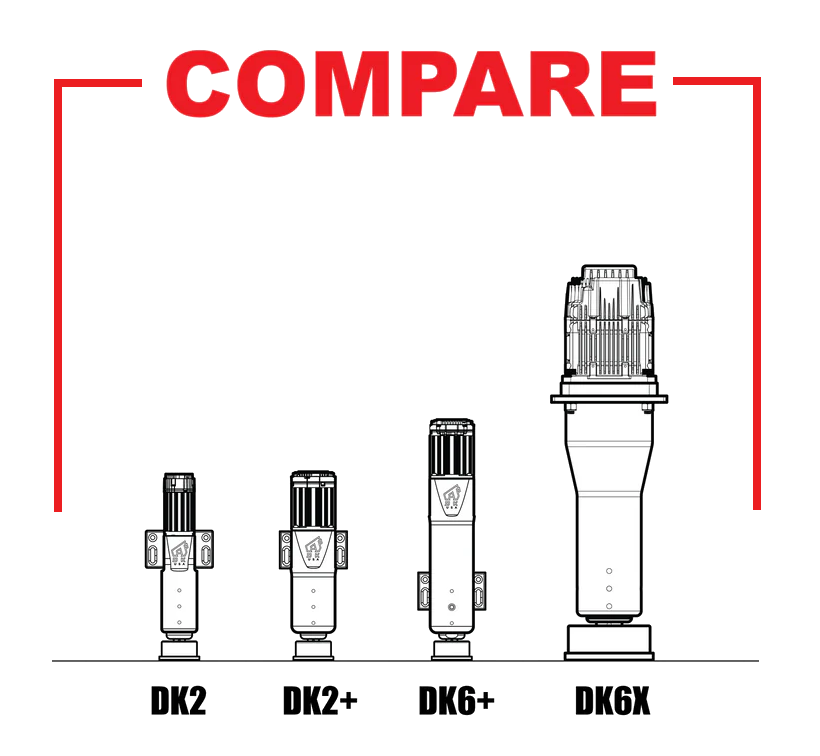

1. Turn-Key Motion Systems

Turn-Key motion systems are a category of motion systems where the manufacture is completely vertically integrated and is responsible for the complete mechanical, electrical and software systems integration. Sigma Integrale falls into this category as we build our own unique actuators, specialized high voltage motion controllers and unique motion software and algorithms all in-house to optimize for the best price to performance.

Turn-Key system providers control all aspects of mechanical, electrical and software integration.

This means that we specifically build the mechanical features of the actuator, such as sizing the ballscrew for the speed and mass of the motor. Designing the actuator body and bearings for specific side loading and dynamic motion angles. Calculating the float of the foot and the mounting bracket to best transfer the haptic vibrations to the driver. This is done through extensive testing.

On the electrical side we optimize the Sigma controller and tune the motors to best represent our motion algorithms. This means meeting or exceeding various UL/CL electrical certifications for home and commercial use. Various commercial or business insurance companies require such safety certification. Turn-Key systems also feature more advanced embedded controllers capable of processing motion algorithms at much higher rates than Open-Source software running in Windows sometimes on a hobby grade microcontroller.

On the software side, the motion software is fully supported, easy to use and future friendly. We also ensure that the embedded system driving the controller does not over-drive the motors or saturate the motion layers with excessive settings. Check out our FULL SEND VIDEO here to see how we measure and verify DK system performance.

Being able to vertically control all aspects of production ensures that we can best optimize the product for its application. Lowering prices in volume and allowing for a more seamless experience. It also means we can fully support our products from the mechanical actuators, to the electrical controller and the software. There is product accountability with Turn-Key systems or someone to reach for support, but at a premium or higher entry price.

[ Sigma DK2 Turn-Key with everything required to mount to standard extrusion chassis. ]

2. Catalog Motion Systems

Catalog motion systems are where the mechanical and electrical components are often sourced from general industrial automation companies and are combined together with open-source software to provide a more affordable motion solution.

Catalog motion systems use industrial automation parts and components with open-source motion software to achieve a better overall price.

In other words, companies providing Catalog motion systems leverage the volume of established automation industries to repurpose things like drives and components to provide a much better price to the customer. This typically means larger and bulkier components, more wires, complexity and more expensive international shipping.

The level of sourcing or final production also varies with each system provider, but one way to determine if a system is indeed a Catalog system is by the use of industrial drivers or controllers with open source software. Industrial drives are large brick like devices that typically sit inside large cabinets and driver the actuator motors. They are typically do not meet any electrical safety standards and sometimes emit electrical noise that is fine for a machine shop environment but can interfere with more sensitive home devices such as VR headsets. (How I solved the EMI problem in my SimRig)

[ Standard industrial servo drives found in many Catalog style motion systems. ]

The software and algorithms are also open source or a paid license to 3rd party software companies, that doesn't necessarily specialize in motion or are optimized for a broad range of actuators. The open-source systems are often a lot more flexible and move quickly to add new software support and features as compared to Turn-Key system providers, that have to be more methodical and careful with software updates.

Prices for Catalog systems can be significantly lower that Turn-Key systems.

3. Open-Source Motion Systems

Open-Source systems are driven by a passionate online community of enthusiasts. Some of the open-source projects are just wild, with many different designs, complexities and features. These custom designs are constantly being tested, tweaked and experimented with to solve various needs. If you love tinkering and building, we highly recommend joining and adding to this great community. (Check out https://www.xsimulator.net for more information)

Open-Source motion systems, unlike Catalog systems are built completely from the ground up, typically by someone who is technically savvy and loves to build, develop and contribute to the community. Easy to follow mechanical plans and electrical guides are available online for users to follow but most Open-Source systems customize their motion design for their specific needs. Often times you figure things out on your own and leverage the community for guidance on any issues you might have.

For this reason, open-source motion systems appear to be the cheapest, but if you calculate all the time, effort, research and design, than the hours quickly add up. Open-Source systems are hence very inexpensive in parts costs, but very time or capital expensive with users typically spending weeks if not months designing, building and customizing their motion systems.

[ Standard DIY motion system kit. ]

In Summary

Turn-Key motion systems are typically more expensive and better supported as the companies who build them have a complete mechanical, electrical and software integration. These systems are typically more compact, easier to install and maintain. Turn-Key systems are also fully supported but also more expensive starting at $5k USD and can exceed $100k or more in some configurations. We recommend Turn-Key systems for those looking for an frictionless motion experience with full support but at a premium price.

Catalog systems are typically less expensive but more bulky and less refined than turn-key systems. They are often less expensive than Turn-Key systems and can come in various configurations and designs from the supplier. There is limited support available from the supplier or the various 3rd party software partners. These systems often do not meet electrical certifications and hence would not be recommended in professional venues such as sim centers. We recommend Catalog systems for those who are technically more knowledgeable and are also more budget conscious.

Open-Source systems are an amazing community of tinkers and creators who are always testing and developing new system designs. Open-source systems take longer to build, have no direct support and are significantly cheaper when looking at just the price of components and not the total time invested. We highly recommend Open-Source systems for those who are price sensitive, are looking to build something specific and don't mind spending the time to build something from scratch.

We hope this helps you when choosing your next motion system.

Ping us with any questions at info@sigmai.co. ;-)

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.