Our main 3 advantages:

1) Mechanics:

Our system is made entirely from billet. This form of manufacturing using precision CNC equipment gives us very rugged and rigid construction. This also provides excellent concentricity inside the bore of the actuator, meaning the piston does not deflect during operation giving our systems a very long service life under various performance conditions. Our systems are built to last many years without maintenance or service.

Billet CNC construction also means that the haptics or vibrations transfer better through the actuator to the chassis. We have the largest ball screws in the industry and the largest largest piston that is 2" in diameter, electro plated, for smoothness, quite operation and endurance even when side-loaded.

2) Electronics:

We are the only company to use 75-volt DC system architecture, making our motors small but powerful. The 75-volt system also allows for thinner cables and hence better cable management. Amongst the turn key systems, we are also the only company that allows you to disconnect and reconnect the power/data cables from the controller or the actuator, making for an easier installation and cable routing.

We are also the only company that allows for custom cable lengths from actuator to controller to computer of up to 33 meters or over 100 feet. We use a 32-bit real time ARM core processor, for calculating velocity, accelerations and jerk which is unique to the industry.

3) Software and Algorithms:

We use our own in house algorithms and software created with no "effects" based motion. We follow a philosophy of Motion Integrity or giving you what the game gives you without any triggered made up effects.

Effects based motion systems or algorithms can present false positives, or effects being played when they should not be played. Sending false cues to the driver and decreasing the signal to noise ratio.

Our unique remote UI app allows you to tune and change the settings on the fly of your motion system, without switching between windows. It also allows for sim centers to remotely manage the motion system via a simple website.

We have unique motion algorithms, explained in more detail here: sigmaintegrale.com/pages/motion-l that give you PURE motion representation without the gimmicks. Some of our motion layers and algorithms can ONLY be calculated in real-time with our 32-bit ARM based controller.

We follow the first-principle idea of Motion Integrity, or doing what we can do very well and focusing on that, and avoiding gimmicks and effects that at first may appear to solve haptic issues in simulating but ultimately have too many tradeoffs.

Lastly our Dynamic Scaling algorithm that allows more travel to be dynamically allocated to the actuator, so that flight and off-road games feel great even with 2" physical actuator travel.

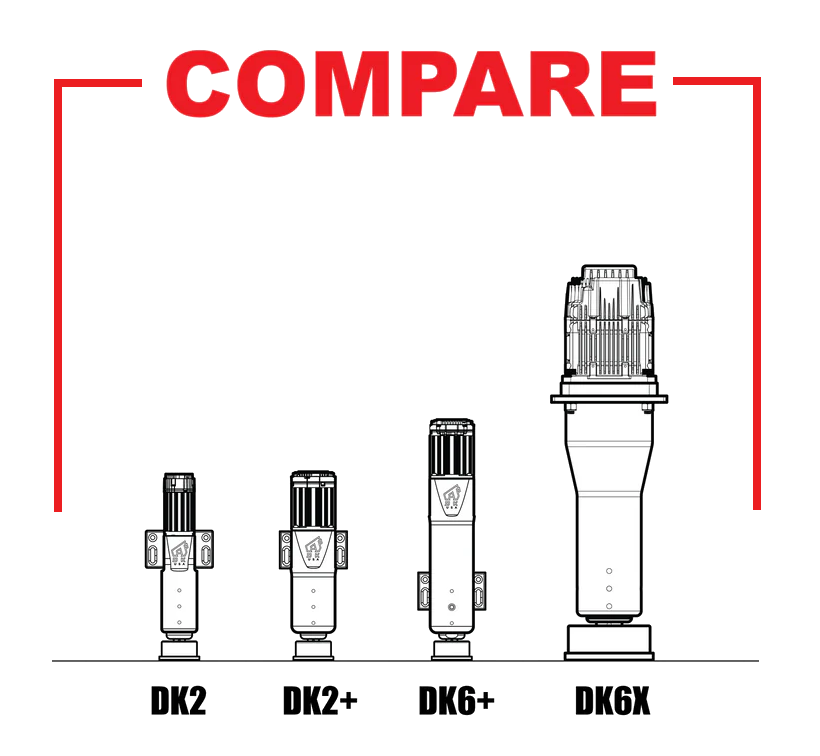

All our systems are made and supported in the USA and range from 500 lbs. to 5000 lbs. total mass supported. For home chassis to real vehicles simulation.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.