DK6+ Motion System

The DK6+ four actuator motion system is our premium 6" (150mm) high-travel solution, engineered for exceptional realism in off-road racing, rally, and flight simulations while also enhancing performance for low-travel vehicles like formula cars. The DK6+ still stays true to Motion Integrity by accurately replicating vehicle dynamics without exaggerating elements like pitch and roll, ensuring unmatched precision and control.

All DK6+ systems now ship in our satin black anodized finish. For side extrusion profile with wider slots, like the ones offered by Sabelt and Trakracer and others, please choose the extended brackets option.

All DK systems include a 3-year electrical and 1-year mechanical warranty.

Extended Warranty is available.

- DK6+ Actuators (3 or 4)

- Mounting Brackets

- Controller

- Cable Set

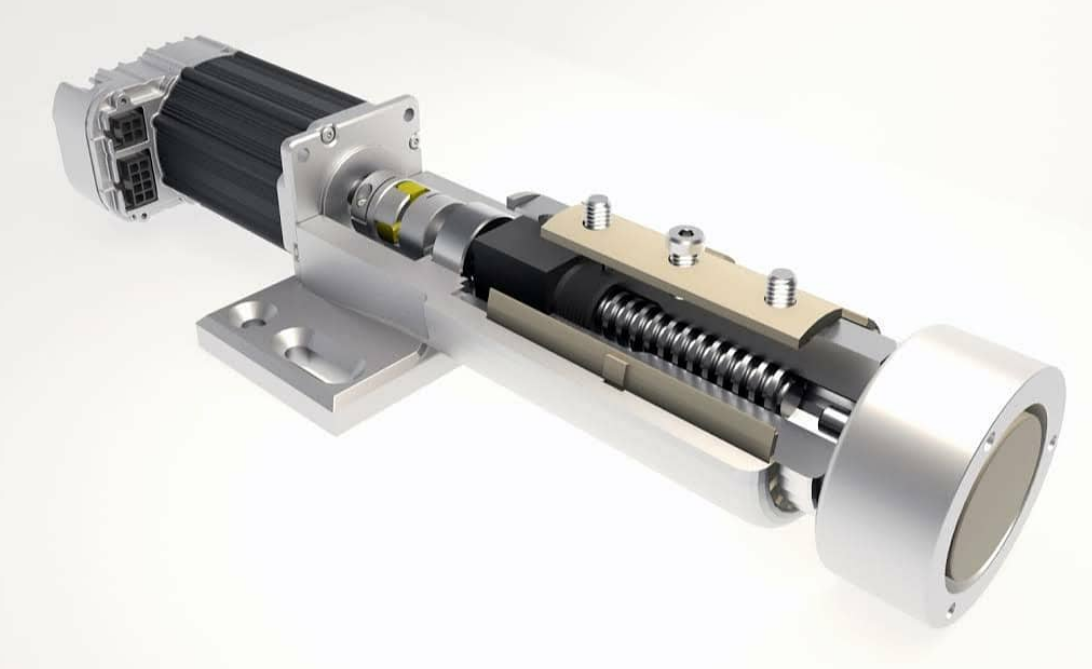

- Made from billet aluminum for optimal haptic transfer

- Features a 6-inch (150mm) solid steel piston for exceptional side loading

- American made motors and controllers for exceptional signal control

- 3-year electrical and 1-year mechanical system warranty

- Provide license free simple to use software with automatic over the air updates

- Years of maintenance free operation with no lubrication required

- Upgradable at any time in the future with our DK Upgrade Program

- USA domestic shipping is 3-5 days.

- All international shipping is typically 5-7 days.

Boosted Media

"Pure telemetry data to the seat of your pants!"

Perfect for immersive experiences in off-road racing, rally, and flight simulation games.

The common saying of "less is more" is really a half-truth. High travel motion systems, if designed well, can better represent the true dynamic nature of vehicle dynamics.

The DK6+ motion system it just that. It shares our philosophy of Motion Integrity and does not over-represent layers, such as pitch and roll, which make control input unnecessarily more difficult. For those that want the most immersive experience available, look no further than the DK6+.

6" OF PURE MOTION

Made in USA, billet machined, powered by our custom motion software.

American made motors

USA made Teknic motors tuned and tested to work with our DK actuators.

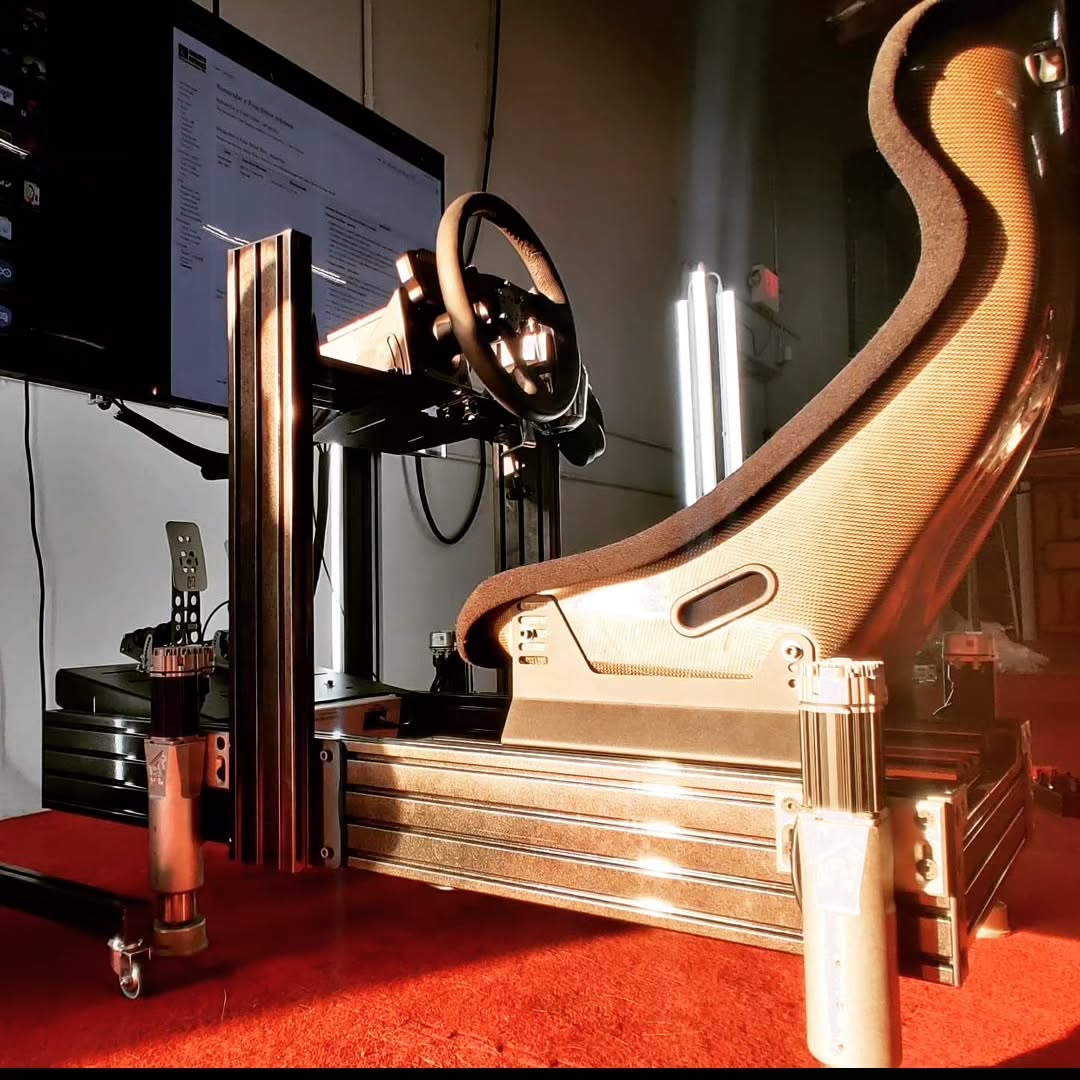

Machined Mounting Plates

Durable and compatible with nearly any aluminum extrusion tubing SIM chassis, such as 160x40m

BILLET MACHINED

Billet aluminum and steel design for incredible strength and haptic feedback

Solid Steel Pistons

Nickel plated solid steel pistons for ultimate strength, quiet operation and durability.

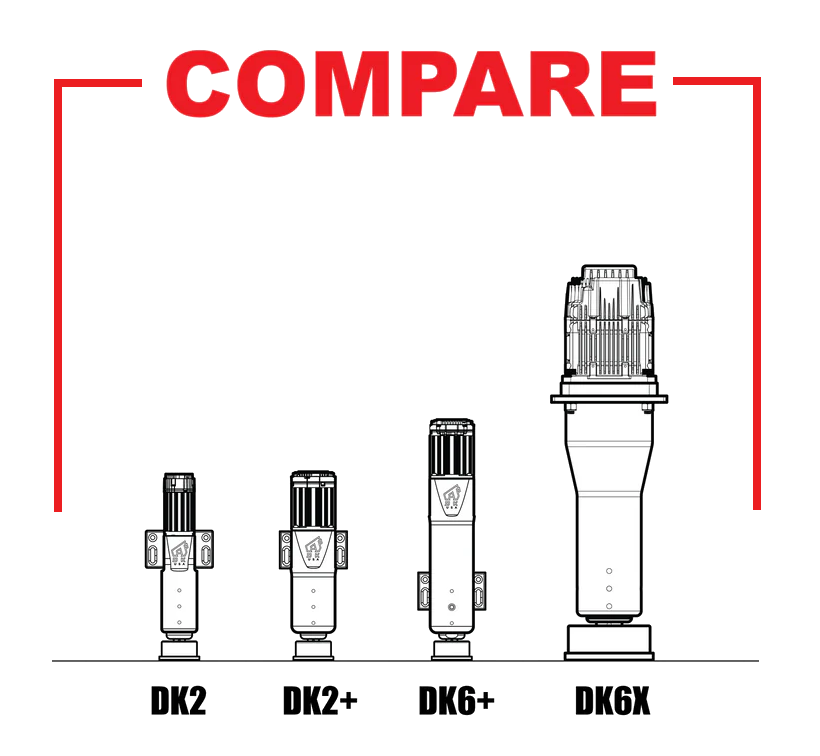

Compare The Competition

Why DK Motion Systems?

Competitors like D-BOX and Qubic use generalized effects, our focus is on pure telemetry-based motion tailored to motorsports. We offer a robust, billet-crafted system with unmatched haptic quality at a more accessible price, without the reseller markup.

01 | Mechanics

DK systems are made from billet using precision CNC equipment. This prevents piston deflection, providing long service life with minimal maintenance required. This design enhances vibration transfer to the chassis. Featuring the industry’s largest ball screws and a 2" or 6" electroplated piston, our systems ensure smooth, quiet, and durable performance, even under side-loading.

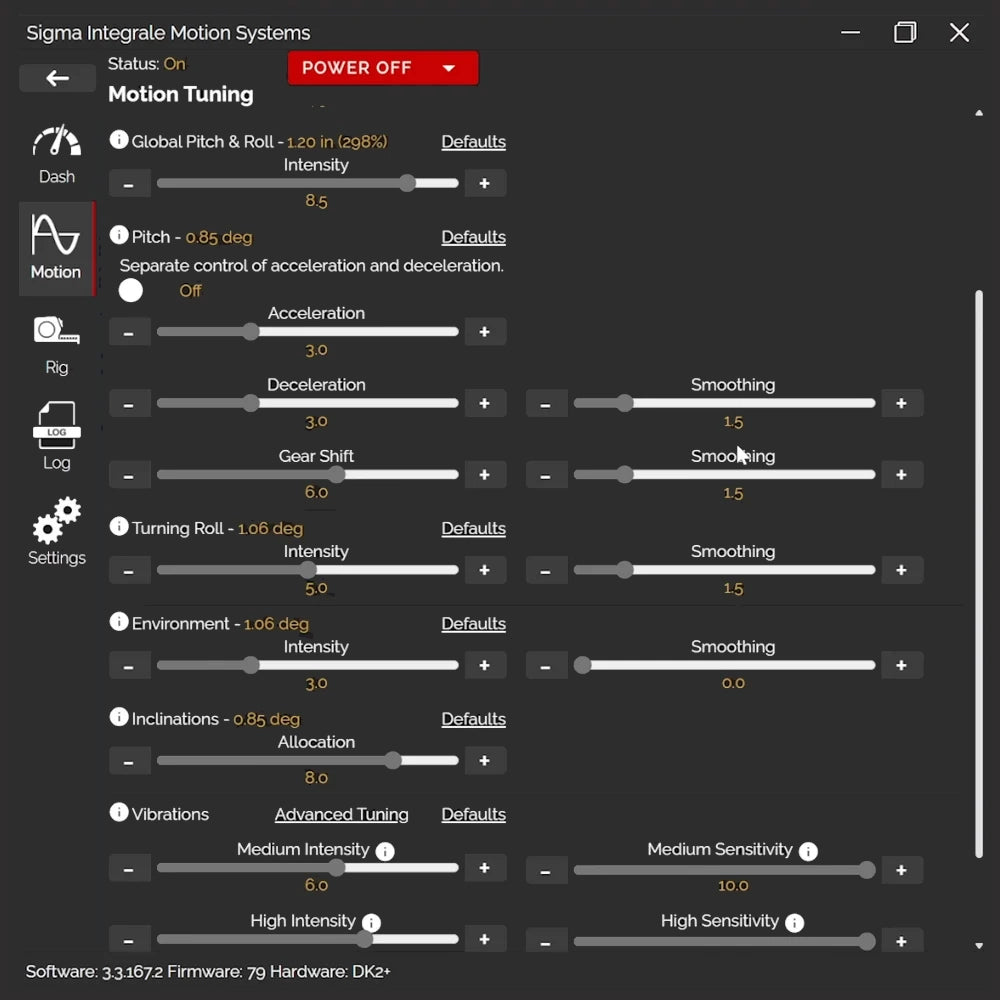

02 | Software & Algorithms

Our proprietary algorithms deliver only game-provided motion, without artificial effects, avoiding false positives and maintaining a sense of realism. The remote UI app enables real-time tuning from your phone. Our Dynamic Scaling algorithm optimizes actuator travel, enhancing experiences in flight and off-road games.

03 | Electronics

We are the only company using a 75-volt DC system, enabling small yet powerful motors and improved cable management with thinner cables. Our system uniquely allows disconnecting and reconnecting power/data cables for easier installation and routing. A 32-bit real-time ARM core processor handles velocity, acceleration, and jerk calculations, setting us apart in the industry.

Specifications

DK6+ Motion System

The ultimate solution for high travel simulation applications such as off-road racing, rally and flight. The 6" stroke allows for better representation of our motion layers with less saturation.

1.5 N-m

7.9"/s @ 2,380 rpm

6″ (150mm)

800 lbs (363 kg)

2,380 rpm

19.000" tall x 3.375" wide

4.9 N-m

20 lbs

Initial Setup

- Follow our hardware installation guide.

- Install and configure the DK Software.

- Enjoy.

Call 1-877-742-4482

Need help? We got you.

We're confidinent our motion system is the easiest turn key solution on the market. However, should you need support, one of our team members willl be happy to help.

Buy Once, Cry Once

Which motion system is right for you?

The DK2 motion system delivers exceptional at-home haptic performance with the same mechanical and electrical capabilities in a smaller, more cost-effective design.

DK2+ and DK6+ motion systems feature larger motors with enhanced torque profiles which translates to more precise bump and curb feedback, quicker directional changes, and a smoother, more natural feel.

The DK6+ features 6" (150mm) of travel, as compared to 2" (50mm) with the DK2 and DK2+.

0.9 N-m

1.5 N-m

1.5 N-m

2" (50mm)

2" (50mm)

6" (150mm)

500 lbs (227 kg)

800 lbs (363 kg)

800 lbs (363 kg)

Impressive company, fantastic motion system. Very easy to set-up and very responsive. Peter answered all my questions and was very helpful.