Made in USA

SIM RACING & FLIGHT MOTION SYSTEMS

Sigma Integrale builds advanced turnkey motion systems for SIM racing and flight. Only Sigma offers Motion Integrity™, ensuring ultra-low latency feedback derived directly from in-game car physics. Every DK motion system is meticulously engineered to replicate the authentic dynamics of vehicle simulations, free from artificial effects. Our team of passionate engineers—who live and breathe racing—has created a product that delivers an unparalleled racing experience. Proudly designed, engineered, and manufactured in California.

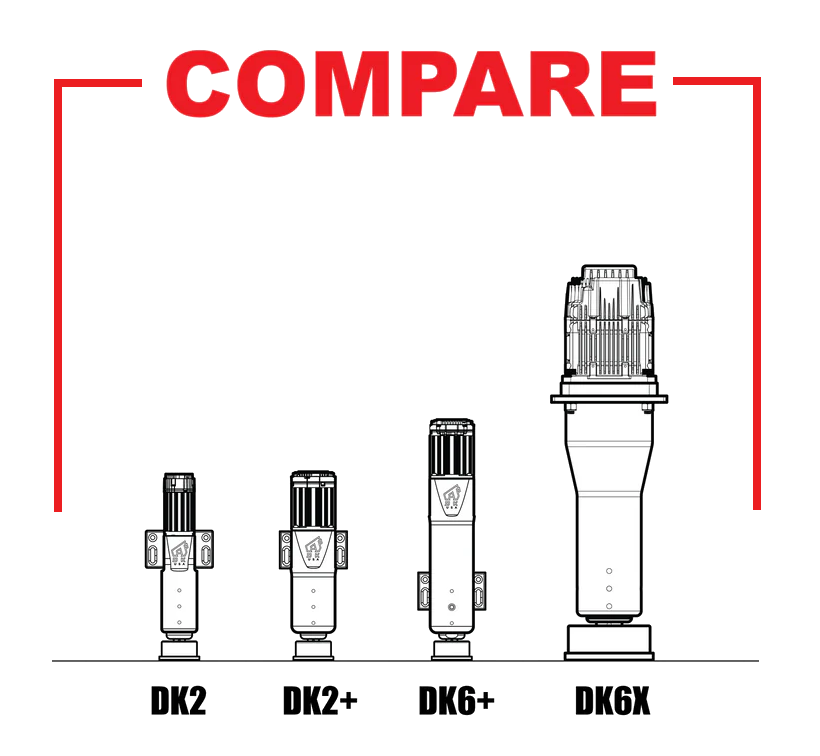

About SigmaWhich motion system is right for you?

The DK2 motion system offers exceptional at-home haptic performance, combining the mechanical and electrical capabilities of our flagship DK+ line in a more compact and cost-effective design.

The DK2+ motion system builds on the DK2 platform, featuring upgraded, larger motors that deliver sharper bump and curb feedback, faster directional changes, and a smoother, more natural driving experience.

The DK6+ motion system takes it even further, incorporating the same upgraded motors while adding 4" of additional travel—perfect for immersive experiences in off-road racing, rally, and flight simulation games.

0.9 N-m

1.5 N-m

1.5 N-m

500 lbs (227 kg)

800 lbs (363 kg)

800 lbs (363 kg)

2″ (50mm)

2″ (50mm)

6″ (150mm)

"

Sigma has an interesting approach to Sim Racing motion which translates pure telemetry data to the seat of your pants rather than using canned effects...

- Boosted Media | YouTube Review

Why DK Motion Systems?

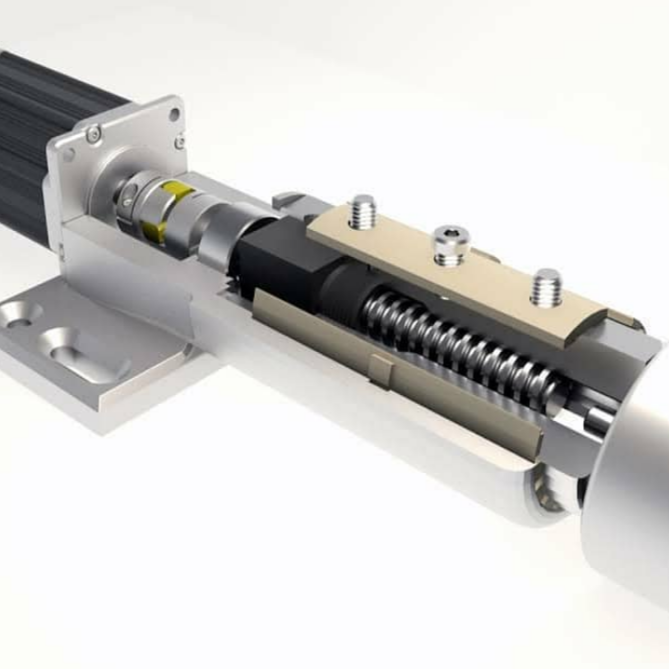

01 | Mechanical

DK systems are made from billet using precision CNC equipment. This prevents piston deflection, providing long service life with minimal maintenance required. This design enhances vibration transfer to the chassis. Featuring the industry’s largest ball screws and a 2" electroplated piston, our systems ensure smooth, quiet, and durable performance, even under side-loading.

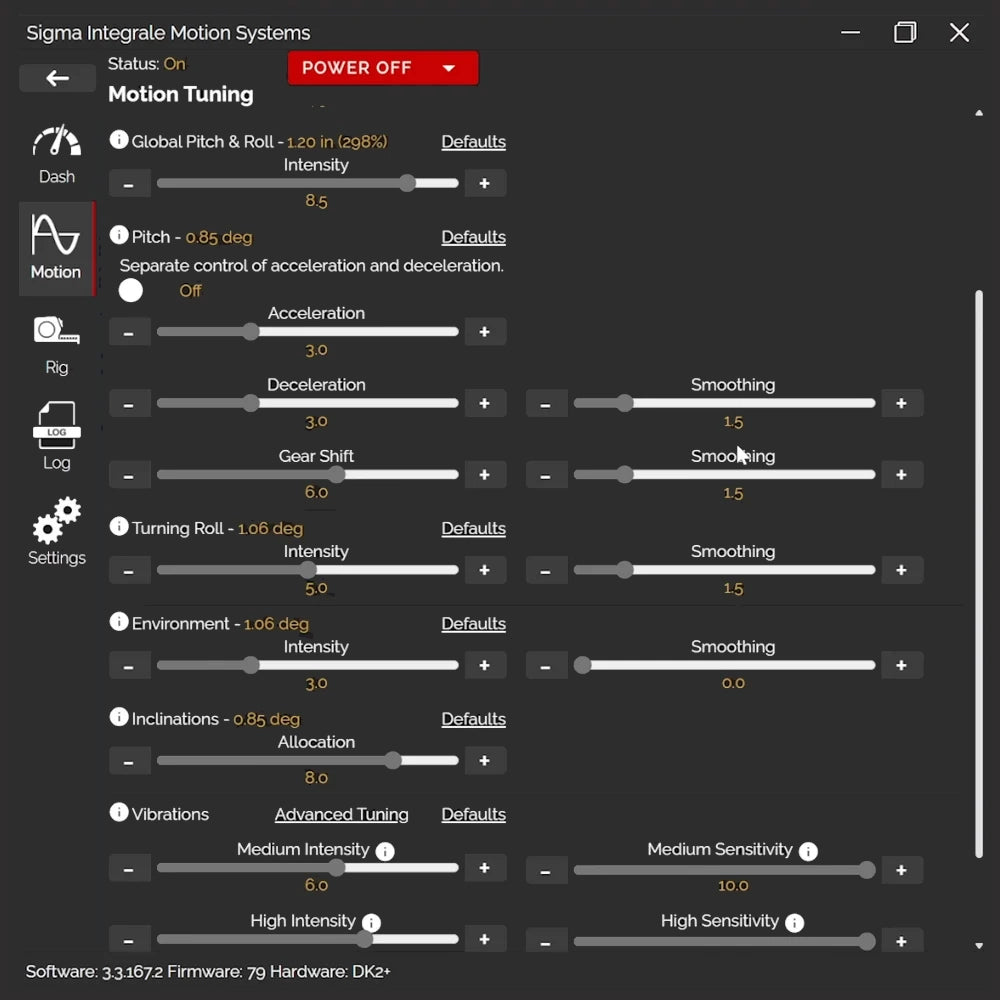

02 | Software

Our proprietary algorithms deliver only game-provided motion, without artificial effects, avoiding false positives and maintaining a sense of realism. The remote UI app enables real-time tuning from your phone. Our Dynamic Scaling algorithm optimizes actuator travel, enhancing experiences in flight and off-road games.

03 | Electrical

We are the only company using a 75-volt DC system, enabling small yet powerful motors and improved cable management with thinner cables. Our system uniquely allows disconnecting and reconnecting power/data cables for easier installation and routing. A 32-bit real-time ARM core processor handles velocity, acceleration, and jerk calculations, setting us apart in the industry.

Play your favorite SIM Games

Call us at 1-877-742-4482

Sigma Support

At Sigma, customer service is at the heart of everything we do. We understand that our success depends on the satisfaction and trust of our customers. That’s why we prioritize responsive, personalized assistance to ensure every customer gets the most out of our motion system. From setup to troubleshooting, our team is committed to providing exceptional support.

News + Updates

When discussing latency in motion simulation, its important to realize that there really is no good way to measure latency between various motion systems. In some ways, the latency numbers don't re...

When we talk about motion systems with clients, we separate the industry into 3 categories or types of motions systems. These are Turn-Key motion systems, Catalog systems and Do-It-Yourself motion ...

I've used a lot of motion systems and nothing compares to Sigma. The speed, tactile feedback, and software is miles above the competition.

In a time where customer service is not a priority in many industries, Sigma's level of hands on customer service is second to none.

Impressive company, fantastic motion system. Very easy to set-up and very responsive.

Have a dk6+ for a couple of months now. Best thing i have for my sim and what a great team. Always ready to help make our sim better every day!